In the realm of electrical installations, the choice of enclosure boxes plays a critical role in ensuring safety, durability, and functionality. Plastic electrical enclosure boxes have gained popularity for their versatility, lightweight nature, and resistance to corrosion. This comprehensive guide explores the various aspects of plastic electrical enclosure boxes, helping you make informed decisions when selecting the right solution for your specific electrical requirements.

Understanding Plastic Electrical Enclosure Boxes

What are Plastic Electrical Enclosure Boxes?

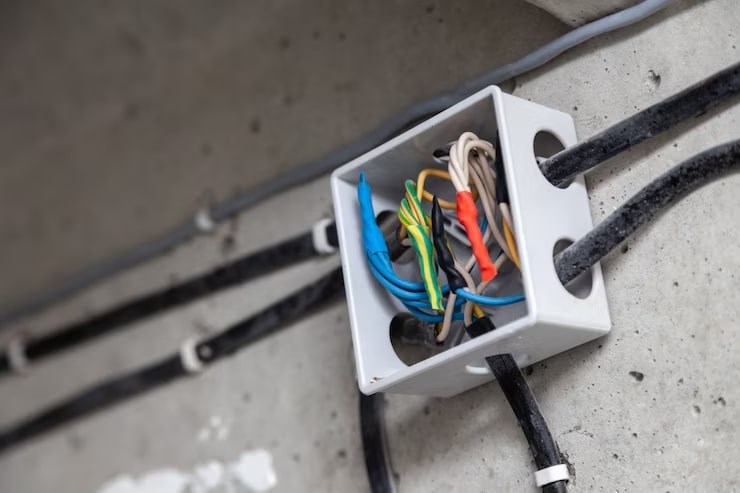

Plastic electrical enclosure boxes are protective cases designed to house electrical components and wiring safely. They are typically made from high-quality thermoplastics such as ABS (Acrylonitrile Butadiene Styrene), polycarbonate, or fiberglass-reinforced polyester (FRP). These materials offer excellent insulation properties, resistance to impact, and protection against environmental factors such as moisture, dust, and chemicals.

Key Features and Characteristics

Plastic electrical enclosure boxes come in various shapes, sizes, and configurations to accommodate different electrical applications. They may feature hinged or removable covers for easy access, mounting options for DIN rails or equipment, and options for transparent or opaque covers depending on visibility needs. These enclosures are designed to meet specific industry standards for electrical safety and reliability.

Benefits of Plastic Electrical Enclosure Boxes

Versatility and Application Flexibility

One of the primary advantages of plastic enclosure boxes is their versatility in application. They are suitable for both indoor and outdoor use, offering protection against UV rays, rain, and extreme temperatures. Plastic enclosures are commonly used in residential, commercial, and industrial settings for housing circuit breakers, switches, relays, and other electrical components.

Lightweight and Durable Construction

Compared to metal enclosures, plastic electrical enclosure boxes are lightweight yet durable. They are easier to handle during installation and require less structural support. Despite their lighter weight, these enclosures provide robust protection against mechanical impact and can withstand harsh environmental conditions without corroding or degrading over time.

Corrosion Resistance and Longevity

Plastic materials used in enclosure boxes are inherently resistant to corrosion, making them ideal for outdoor installations or environments where exposure to moisture and chemicals is common. This resistance contributes to their longevity and reliability, ensuring prolonged service life and minimal maintenance requirements.

Factors to Consider When Choosing Plastic Electrical Enclosure Boxes

Environmental Conditions and Ratings

Before selecting a plastic enclosure box, assess the environmental conditions where it will be installed. Consider factors such as temperature fluctuations, exposure to UV radiation, humidity levels, and the presence of corrosive substances. Choose an enclosure box with appropriate IP (Ingress Protection) ratings to ensure it provides adequate protection against dust and water ingress.

Size and Mounting Options

Evaluate the size requirements based on the number and size of electrical components that need to be housed within the enclosure. Consider whether additional space is needed for future expansions or modifications. Select an enclosure box with suitable mounting options, such as wall mounting, pole mounting, or freestanding configurations, to ensure compatibility with your installation site.

Accessibility and Security Features

Assess the accessibility features of the enclosure box, such as ease of opening/closing covers, availability of lockable options for added security, and provisions for cable entry and management. These features are crucial for maintaining safety during maintenance and ensuring protection against unauthorized access to electrical components.

Installation and Maintenance Considerations

Installation Guidelines

Follow manufacturer guidelines and industry standards when installing plastic electrical enclosure boxes. Ensure proper grounding and bonding of electrical components to prevent electrical hazards. Securely mount the enclosure to a stable surface using appropriate hardware to withstand vibrations and mechanical stress.

Routine Maintenance

Regularly inspect the enclosure box for signs of wear, damage, or deterioration. Clean the exterior and interior surfaces to remove dust, debris, or contaminants that may affect performance. Check seals and gaskets periodically to ensure they remain intact and effective in maintaining the enclosure’s IP rating.

Conclusion

Plastic electrical enclosure boxes offer a reliable and cost-effective solution for safeguarding electrical components in various applications. By understanding their features, benefits, and considerations for selection, you can choose the right enclosure box that meets your specific electrical needs while ensuring long-term durability and safety.

When selecting a plastic enclosure box, prioritize factors such as material quality, environmental compatibility, size requirements, and accessibility features. By making informed decisions and following installation and maintenance best practices, you can optimize the performance and longevity of your electrical installations with confidence in the chosen plastic electrical enclosure box.