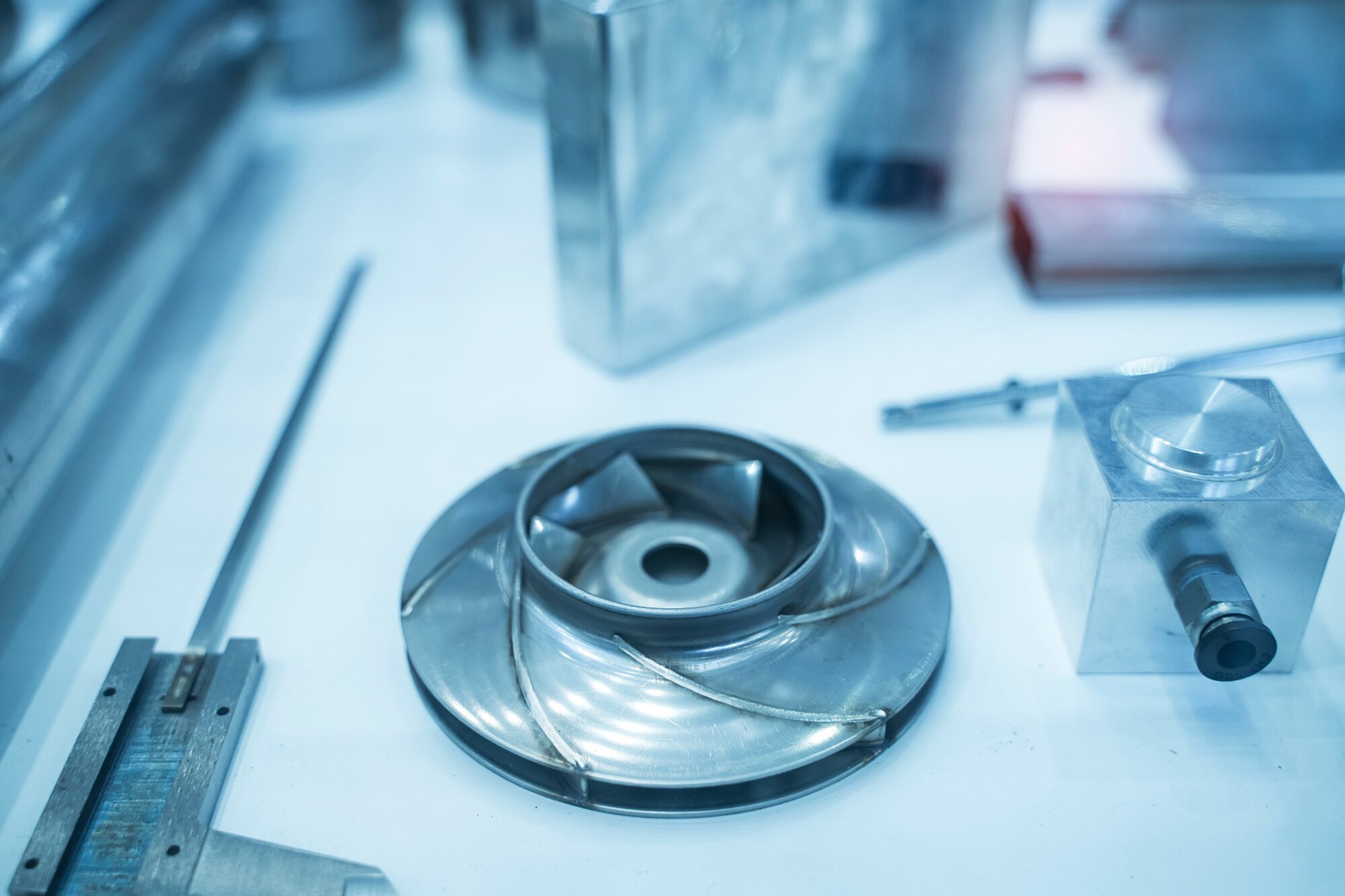

In the realm of metalwork projects, choosing the right investment casting process can make or break your endeavor.

Understanding the nuances of various metal casting techniques is crucial. This is whether you’re crafting intricate designs or producing durable stainless steel components.

This guide aims to simplify the decision-making process. That way, you can ensure both quality and cost-effectiveness for your next project.

So, if you are curious to learn more about investment casting, this article is for you. Read on!

Understand Material Compatibility

When choosing an investment casting process, it’s essential to consider the compatibility of materials. Each metal has different properties and characteristics that can affect the final product.

For example, stainless steel is known for its high strength and corrosion resistance. This makes it a popular choice for industrial applications. However, this type of steel can be challenging to cast. And, this can be due to its high melting point and low fluidity.

On the other hand, aluminum is relatively easy to cast. This can be due to its low melting point and excellent fluidity. However, it may not be suitable for certain applications that require higher strength or durability.

Therefore, understanding how different metals behave during the casting process is crucial. This is especially needed in determining which process will yield the best results for your desired material.

Evaluate Design Complexity

Different methods have their limitations when it comes to producing intricate and detailed patterns. For example, traditional sand casting may not be suitable for highly complex designs. This is because it relies on manual labor for pattern-making and mold creation.

On the other hand, ceramic shell casting or lost wax casting can achieve more intricate designs. This can be due to the use of precise molds.

It’s essential to evaluate the level of detail and precision required for your project. Do this before deciding on a specific stainless steel investment casting process.

This will ensure that you choose a method that can accurately produce your desired design without compromising quality.

Consider Production Volume and Cost

Some methods are more suitable for high-volume production. Others may be better suited for smaller runs.

For example, sand casting is a cost-effective option for high-volume production due to its lower tooling costs. On the other hand, ceramic shells or lost wax casting can achieve higher precision. But, they may come at a higher cost.

Evaluating your project’s production volume and budget will help you determine which investment casting process can meet your needs. You can do this without exceeding your resources.

Take note that precision casting methods may come at a higher cost. So, it’s essential to strike a balance between quality and budget.

If you work with a metalworking partner, they can help you find the ideal process that meets your project’s specific requirements and budget.

Choose the Right Investment Casting Process for Your Project

Choosing the right investment casting process for your project requires careful consideration. By evaluating these aspects and selecting the most suitable process for your specific project needs, you can ensure high-quality results while also staying within budget.

So, take the time to research and choose the best investment casting process for optimal success. Now that you have a better understanding of the key factors involved in this decision, go forth and create with confidence!

Should you wish to explore other topics, head to our blog page. We’ve got more!

Keep an eye for more news & updates on TimesAnalysis.Com!